It should also be noted that the stress–strain curve for the same-strength concrete may be of different shapes if the condition of loading varies appreciably. If the unit weight is taken as 144 lb/ft 3, the resulting expression for modulus of elasticity is

For normal-weight concrete, the unit weight w c will vary with the mix proportions and with the character and size of the aggregates. This expression is valid for concretes having w c between 90 and 160 lb/ft 3.

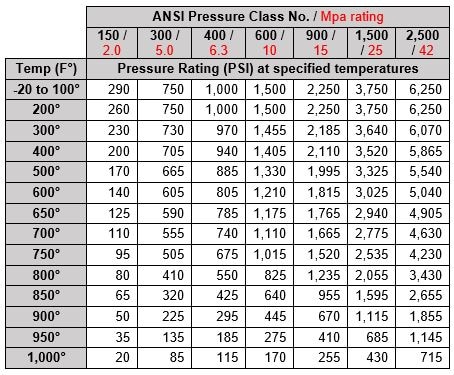

#PSI MEANING IN CONCRETE CODE#

The ACI Code provides the accepted empirical expression for modulus of elasticity :Į c = modulus of elasticity of concrete in compression (psi)į c ′ = compressive strength of concrete (psi) At low and moderate stresses (up to about 0.5 f c ′ ), concrete is commonly assumed to behave elastically. Even if we assume a straight-line portion, the modulus of elasticity is different for concretes of different strengths. It may also be observed that the slope of the initial portion of the curve (if it approximates a straight line) varies with concretes of different strengths. Therefore, there exists no constant value of modulus of elasticity for a given concrete because the stress–strain ratio is not constant. For concrete, however, we observe that the straight-line portion of the plot is very short, if it exists at all. The slope of the straight line is the modulus of elasticity. For steel, where stresses are below the yield point and the material behaves elastically, the stress–strain plot will be a straight line. The initial slope of the curve varies, unlike that of steel, and only approximates a straight line. Higher-strength concretes are more brittle and will fracture at a lower maximum strain than will the lower-strength concretes. Stress then decreases, accompanied by additional strain. The curves shown in Figure 1 represent the result of compression tests on 28-day standard cylinders for varying design mixes .Ī review of the stress–strain curves for different strength concretes reveals that the maximum compressive strength is generally achieved at a unit strain of approximately 0.002 in./in. Figure 1 Typical stress–strain curves for concreteĬurrently, 28-day concrete strengths ( f c ′ ) range from 2500 to 9000 psi, with 3000 to 4000 psi being common for reinforced concrete structures and 5000 to 6000 psi being common for prestressed concrete members.Ĭoncretes of much higher strengths have been achieved under laboratory conditions. Note in Figure 1 that f c ′ is not the stress that exists in the specimen at failure but that which occurs at a strain of about 0.002. The compressive strength so determined is the highest compressive stress to which the specimen is subjected. The test involves compression loading to failure of a specimen cylinder of concrete. For calculations, f c ′ is frequently used with the units kips per square inch (ksi).Ī test that has been standardized by ASTM C39 is used to determine the compressive strength ( f c ′ ) of concrete. The compressive strength of concrete is denoted f c ′ and is assigned the units pounds per square inch (psi). With concrete used principally in compression, the compressive stress–strain curve is of primary interest. It is generally accepted that the behavior of a reinforced concrete member under load depends on the stress–strain relationship of the materials, as well as the type of stress to which it is subjected.

0 kommentar(er)

0 kommentar(er)